Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-57750238

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-57750238

info@kscrown.com

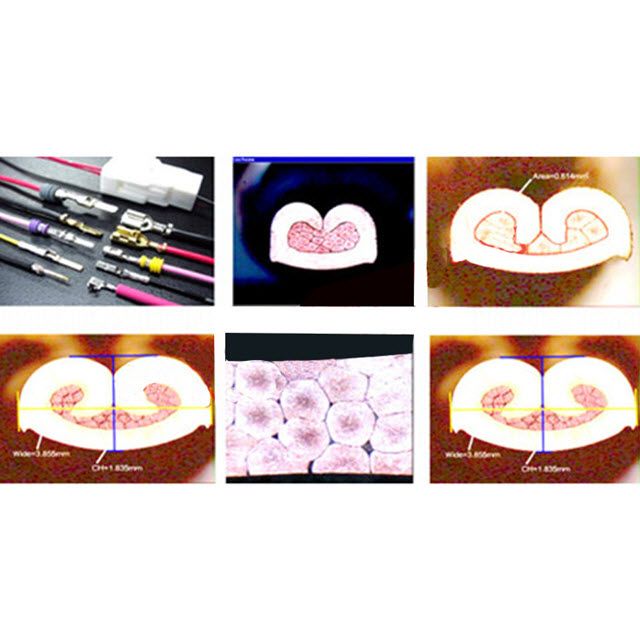

This portable measuring equipment designed professioanlly to guarantee high quality for wire harness industry. It will take 3-5 minutes to go through procedures such as Incision, erosion, cross-sectional image processing, testing analysis, records and so on. It improves the quality inspect speed of the terminal cross section greatly.

|

Model:

|

|

○ The portable terminal cross section analyzer is a precision detection and analysis equipment specially developed for the quality inspection of the wire harness industry.

○ The Crimp Cross-sectional Analysis System is composed of cutting and grinding integrated equipment, optical sampling, corrosion cleaning, cross section image acquisition system, wire harness terminal picture measurement and analysis system imported from Japan.

○ Quick sample making and monitoring can be done with our crimp cross-section analysis system.

○ The ergonomic design and modular combination make the operation more convenient and fast.

○ The processing and analysis of one terminal can be completed within 5 minutes, which greatly improves the speed of terminal cross section quality inspection.

○ The operation is simple, convenient and fast. It adopts Japan's high-definition image acquisition system and ensures accurate measurement analysis to protect your production.

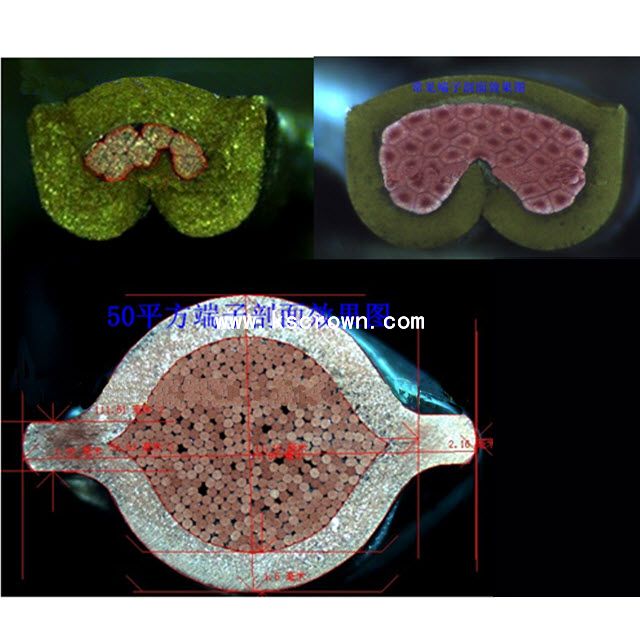

○ High performance microscopes and special software can measure length and calculate area simply and correctly.

○ When observing objects in ultra-high definition, it can generate upright three-dimensional spatial images with strong stereoscopic sense, clear imaging and clear and wide imaging.

| Model | WL-SE5 |

| Control System | Adopt Japanese Mitsubishi PLC controller - SBL |

| Module cut range | 0.13 ~6.00 mm2 |

| Rotate speed | 2800 rpm (Imported motor from Germany) |

| Cut speed | 2 mm / sec |

| Cut wheel inner diameter | 21.7 mm, OD:105 mm, thickness: 0.5 mm (Germany imported, delicate and durable) |

| Module grind speed | 2800 rpm (Imported motor from Germany) |

| Z-axis slightly tuning range | 0.00~5.00 mm |

| Special sandpaper OD | 100 mm |

| X-axis shift | Japanese Panasonic servo motor |

| Eclipse partial electrolysis | Up to 6 mm2 |

| Electrolysis time | 5~30 sec |

| Picture ingestion | High quality, low distortion optical instrument with 10x eyepiece |

| Amplify multiple | 0.75x, 1x, 1.5x, 2.0x, 2.5x, 3.0x, 3.5x, 4.0x, 4.5x, 5.0x(0.5 stuck position shift technology) |

| Tooth pitch multiple | 0.75x, 1x, 1.5x, 2.0x, 2.5x, 3.0x, 3.5x, 4.0x, 4.5x, 5.0x(0.5 stuck position shift technology) |

| Observation range | 1.2~8.2 mm(X-axis direction) |

| Observation feature 1 | Ultra-bright white LED light source can be controlled infinitely |

| Observation feature 2 | X Y Z-axis mobile platform with slightly tuning |

| Range | +/- 6 mm(Three-dimensional) |

| Analysis and file record | Japanese industrial HD video system 3 megapixel camera, USB 2.0, and Section-ms software |

| Tool certification |

Enhanced measurement tools including compression ratios have been certified in the automotive/home appliance/IT industry |

| Voltage and watt | 220VAC, 50Hz, 300W |

| Weight | 30kg |

| Dimensions | 490 mm (L) x 340 mm (W) x 340 mm (H) |